Efficient robotic solutions

for production processes

In today’s rapidly evolving world of industrial automation, robotics play a crucial role in optimizing production processes. Whether it’s machine tending, material handling, palletizing, or packaging tasks, robots ensure higher efficiency, shorter lead times, and reduced costs. Explore below how various robotic applications can elevate your production to the next level.

Machine tending

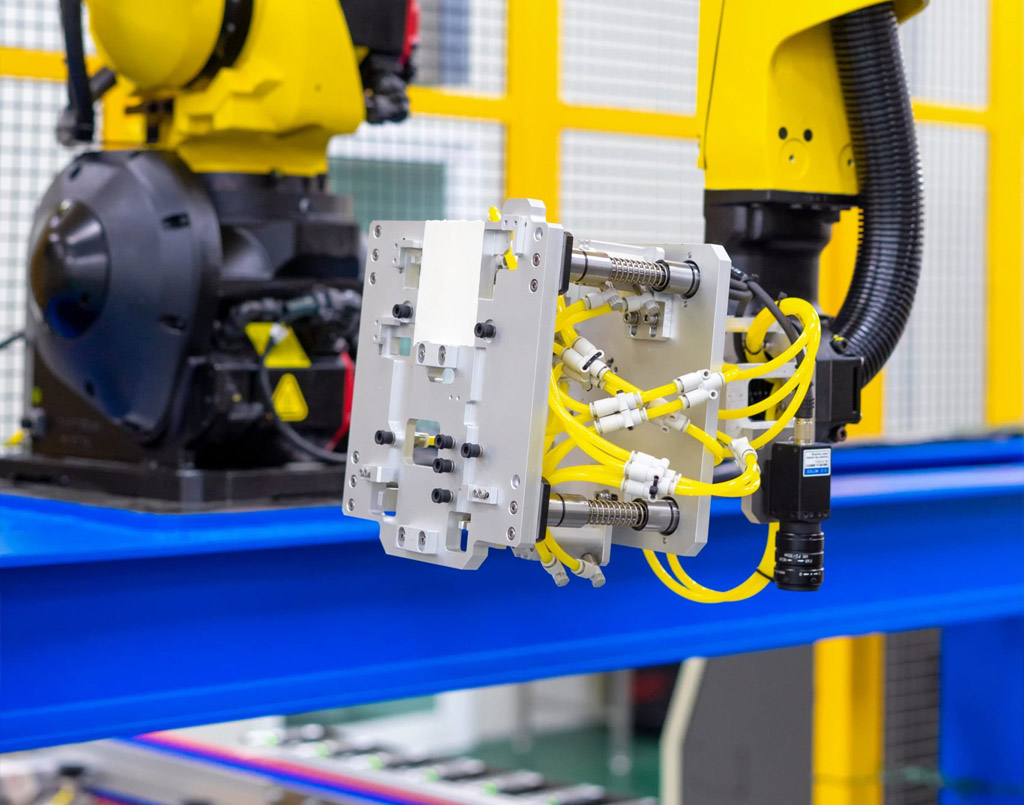

Being at the right place at the right time is a well-known saying which is key to success. This is also true for machine tending solutions. CNC machining a product can take minutes or even hours. As soon as the machine is finished, you want to load a new product quickly to have the uptime as high as possible. Trusting the machine tending application to an industrial robot offers the solution. The robot is often equipped with a dual gripper system with which it can load and unload the product more efficiently, complementing the machine tending solution.

Another perfect example is unloading injection moulding machines. Often a dangerous working environment for humans because of the press. With the modern communication protocols, the “handshake” between robot and machine is quick, so you have maximum uptime. As this is a high-volume industry, you must robotize to keep up with the competition.

Material handling

Modern high-speed production environments can take a toll on human operators because they require uninterrupted speed, accuracy, and agility. When robots take over tasks such as processing materials, people can focus on more important tasks while still achieving the same high production speeds. These robots not only improve productivity but also save valuable production time. Material handling is a collective term for different applications. For example, palletizing, machine loading, or packaging robots.

Are you wondering where to start? Let us take a look at your production needs. Together with partners, we offer efficient solutions that increase productivity, reduce costs and save valuable production time.

Palletizing

Palletizing or end-of-line palletizing refers to stacking products on a pallet. This is one of the main repetitive tasks with which you can significantly increase the efficiency of your organization—for example, palletizing boxes at the end of the production line.

There is also room for flexibility. Do you produce products of different sizes on different days of the week? Or do you produce those products simultaneously? A well-engineered, flexible automation plan can offer the solution.

Furthermore, the end-of-arm tooling plays a vital role in the palletizing process. The robot can conduct multiple tasks using a multifunctional tool, such as picking the separation sheet or handling an empty pallet. This is why it is recommended to work with one of our partners to get the most out of your palletizing application.

Packaging

There are many repetitive tasks our packaging robots are keen to conduct in the manufacturing process! Labeling, filling, or palletizing are all pick-and-place applications one cannot do as accurately as an industrial robot. In many industries, products are packed in boxes. As a result, they can be handled more efficiently in the logistics process. Combining packaging robots with vision technology will significantly increase flexibility in the production process.

Well-designed gripper technology is essential for the packaging process. This ensures that the robot can be used anywhere in the process. For example, let the robot position boxes so that they can be automatically assembled, then pack them. This way, you get the most out of your automation.

Vision technology

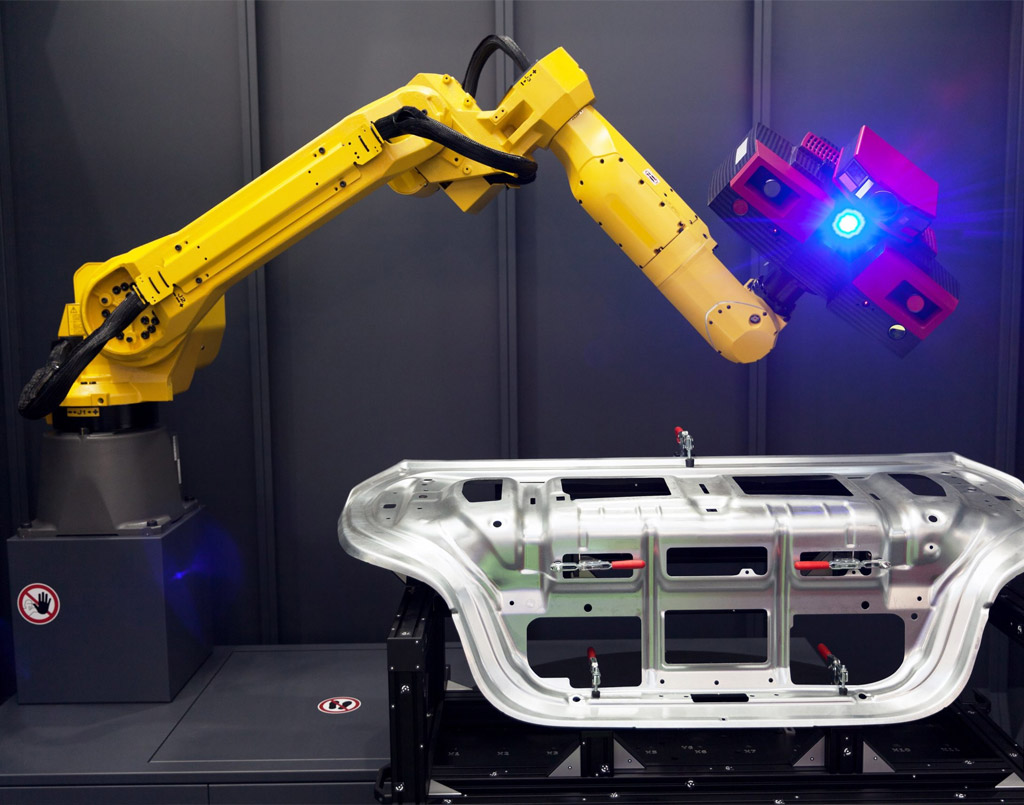

Industrial robots are used in brilliant, inventive production solutions. All thanks to integrators, programming every instruction, so the robot knows where to pick the product. With the addition of vision technology, the robot will have a pair of eyes with which it can process information. To precisely locate a product, sometimes it is easier to see it for yourself, right?

Companies that value quality will benefit even more. The robot can decide whether it picks the product by running an approval check using vision technology. When the product does not meet the specifications, what’s the point for a packaging robot to pack it anyway?

Vision technology offers many possibilities for your production process. We happily explain the options for your application, after which we can connect you to an expert in your field of industry.